- 您现在的位置:买卖IC网 > Sheet目录203 > APLVD400 (Red Lion Controls)VOLTMETER AC 3 1/2-DIGIT

�� �

�

�

�Division� =� (Maximum� Output)� x� D.P.P.� =� (10)� x� 1000� =� 16.7� (D.F.)�

�TYPICAL� VOLTAGE� &� CURRENT� MEASUREMENT� APPLICATIONS�

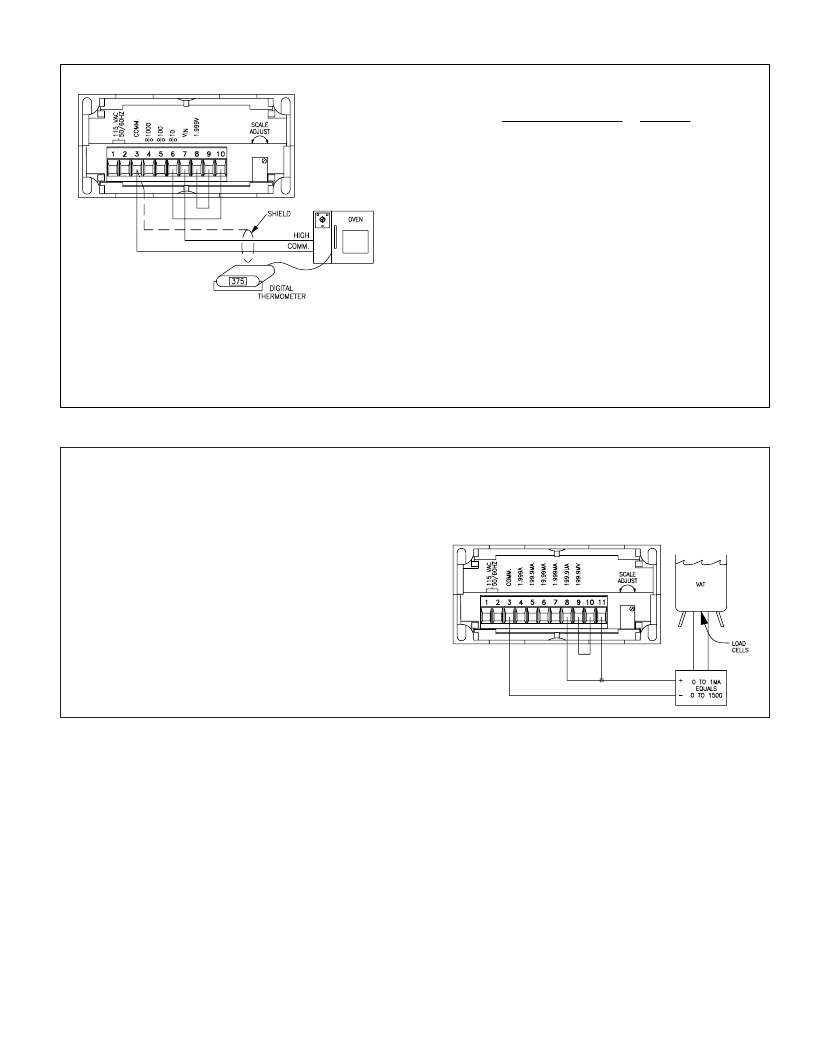

�TEMPERATURE� MONITORING� IN� A� BISCUIT� BAKING� OPERATION�

�scaling� is� required.� The� first� thing� that� must� be� done� is� to� determine� what�

�division� factor� is� required.� Use� the� equation� discussed� in� the� text.�

�Factor� (Desired� Display)� (600)�

�It� can� be� seen� that� the� division� factor� falls� between� 12� and� 105� (See�

�“Scaling� Connection� Diagrams”)� .� This� is� accomplished� by� connecting� a�

�jumper� between� “÷10”� (Terminal� 6)� and� Terminal� 10� (the� 1.999� V� basic� input)� ,�

�and� a� jumper� between� Terminal� 9� and� Terminal� 8.� Then,� using� 2� conductor�

�shielded� wire� to� minimize� noise� pickup,� the� common� of� the� temperature�

�controller� output� is� connected� to� “COMM.”� (Terminal� 3)� and� the� “HIGH”�

�side� of� the� output� of� the� temperature� controller� is� connected� to� “V� IN� ”�

�(Terminal� 7)� .� The� shield� is� also� connected� to� “COMM.”� (Terminal� 3)� .�

�The� Apollo� is� now� ready� to� be� calibrated.� The� baker� has� access� to� a� portable�

�digital� thermometer.� So� in� this� case,� calibration� will� be� accomplished� by�

�causing� the� Apollo� indicator� to� agree� with� the� portable� digital� thermometer.�

�The� baker� sets� his� oven� to� his� normal� baking� temperature� of� 375°F.� He� installs�

�the� temperature� probe� in� the� oven� and� waits� for� it� to� reach� equilibrium.� After�

�A� biscuit� baker� has� temperature� controllers� on� his� ovens� that� have� a� dial� for�

�setting� the� temperature� of� his� ovens.� He� would� like� to� have� a� digital� display� of�

�his� temperature� for� ease� of� monitoring.� He� has� determined,� by� talking� to� the�

�temperature� controller� manufacturer,� there� is� a� 0� to� 10� VDC� voltage� available�

�from� the� controller,� that� represents� a� temperature� of� approximately� 0� to� 600°F.�

�An� Apollo� DC� voltage� indicator� is� ideally� suited� to� this� application.� It� is�

�apparent� that� a� standard� range� will� not� satisfy� this� requirement;� therefore,� field�

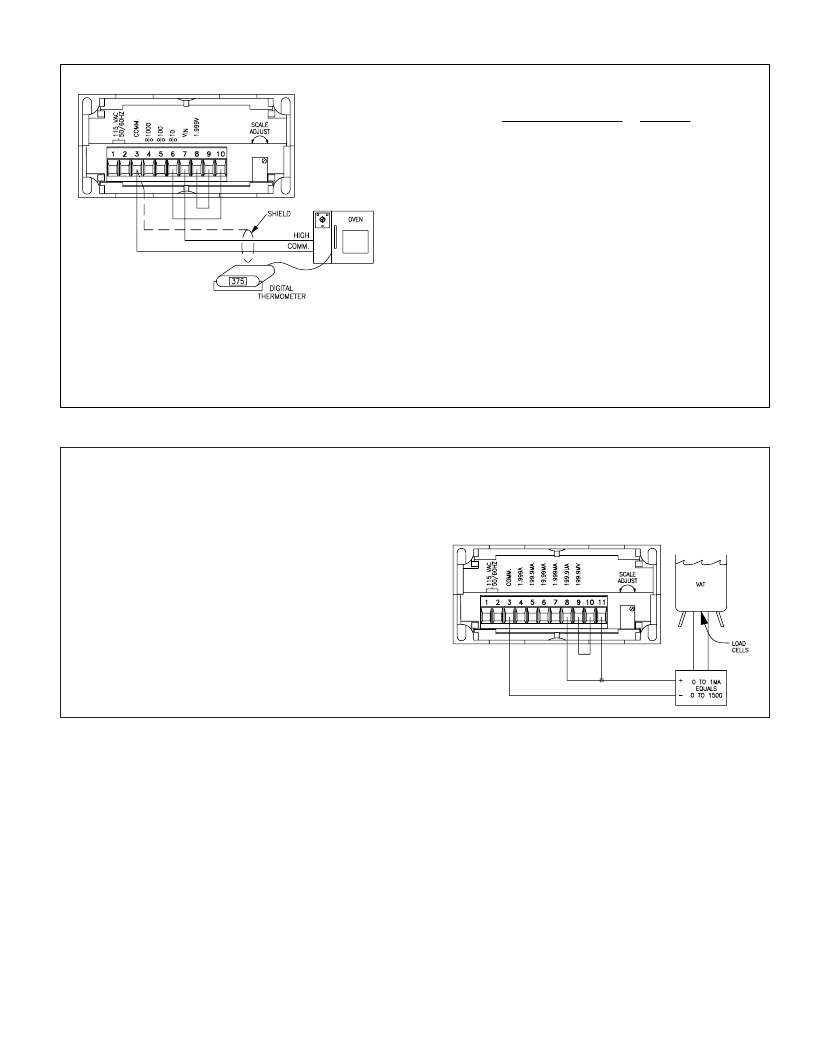

�VOLUME� INDICATION�

�A� manufacturer� who� uses� vats� of� chemicals� in� his� process� has� been� using�

�the� output� of� load� cells,� connected� to� a� circuit� that� in� turn� drives� a� 1� mA� DC�

�analog� meter� movement� to� display� how� full� the� vat� is.� The� meter� dial� is�

�calibrated� 0� to� 1500� gallons.�

�An� Apollo� DC� current� indicator� is� ideally� suited� to� this� application.� It� is�

�apparent� that� a� standard� range� will� not� satisfy� this� requirement� and� field�

�scaling� is� required.�

�It� can� be� seen� that� the� 1� mA� for� 1500� gallons� can� not� be� accomplished� using�

�the� 1.999� mA� range;� however,� the� maximum� input� of� 1mA� does� not� exceed�

�the� maximum� input� on� the� 199.9� μA� range,� so� this� range� is� selected.� This� is�

�accomplished� by� connecting� the� jumpers� as� described� in� the� “Scaling”� section�

�[e.g.� from� “199.9� μA”� (Terminal� 8)� to� Terminal� 11� and� a� jumper� between�

�Terminal� 10� and� the� “199.9� mV”� basic� input� (Terminal� 9)]� .� Then,� the� Apollo�

�is� connected� in� the� circuit� to� replace� the� analog� meter� by� connecting� the�

�“199.9� μA”� (Terminal� 8)� where� the� “+”� terminal� of� the� analog� meter� was�

�connected,� and� connecting� the� “COMM.”� (Terminal� 3)� where� the� “-”� terminal�

�of� the� analog� meter� was� connected.�

�The� Apollo� is� now� ready� to� be� calibrated.� The� operator� fills� the� vat� until� it�

�is� completely� full� and� he� knows� he� has� 1500� gallons.� He� then� adjusts� the�

�5�

�the� oven� has� stabilized,� at� its� operating� temperature,� the� baker� simply� adjusts�

�the� “coarse”� scaling� adjustment,� located� at� the� rear� of� the� unit,� until� the� display�

�is� close� in� value� to� that� indicated� on� the� digital� thermometer.� He� then� removes�

�the� “fine”� scaling� access� plug� and� adjusts� the� “fine”� scaling� adjustment� until�

�the� display� agrees� with� the� digital� thermometer.� He� replaces� the� access� plug� to�

�keep� dust� out� of� the� Apollo.� The� Apollo� voltmeter� now� indicates� the� oven�

�temperature� and� the� baker� can� monitor� his� temperature� precisely.�

�coarse� scaling� adjustment� on� the� rear� of� the� Apollo� indicator� until� the� display�

�reads� approximately� 1500.� He� then� removes� the� “fine”� scaling� adjustment�

�access� plug� and� adjusts� the� “fine”� scaling� adjustment� until� the� display� reads�

�exactly� 1500.� He� replaces� the� access� plug� to� keep� dust� and� water� out� of� the�

�Apollo.� The� Apollo� current� meter� now� indicates� the� exact� number� of� gallons�

�in� the� vat.� No� decimal� point� is� selected� because� the� resolution� is� 1� gallon.�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

APMR0016

MOD APMR 3-PH VAULT DET DIN RAIL

APS INT2012

INVERTER 2000W 230VAC OUT

APS1012

INVERTR 1000W 12VDC 2OUT W/CHRGR

APS1250

INVERTER W/BATT CHARGE 1250W

APS1524

INVERTER 1500W HARDWIRE OUTPUT

APS2424

INVERTR 2400W 24VDC W/CHRGR

APS2448UL

INVERTER 2400W 48VDC OR 120VAC

APS3636VR

INVERTER 3600W 36VDC OR 120VAC

相关代理商/技术参数

APLVD410

制造商:Red Lion Controls 功能描述:DC 230V 制造商:Red Lion Controls 功能描述:DC, 230V

APLW6-LDS

制造商:Leviton Manufacturing Co 功能描述:

APLW8-LDS

制造商:Leviton Manufacturing Co 功能描述:

APM

制造商:Cliff Electronic Components 功能描述: 制造商:Cliff Electronic Components 功能描述:PLUG XLR FREE 3POLE 制造商:Cliff Electronic Components 功能描述:PLUG, XLR, FREE, 3POLE 制造商:Cliff Electronic Components 功能描述:PLUG, XLR, FREE, 3POLE, Gender:Plug, No. of Contacts:3, Contact Termination:Solder, Connector Mounting:Cable, Connector Body Material:Metal, Contact Plating:Silver, SVHC:No SVHC (20-Jun-2013), Cable Diameter Max:7.2mm, Colour:Black, , RoHS Compliant: Yes

AP-M

制造商:Atmel Corporation 功能描述:

APM002GM1AN-2T

功能描述:Solid State Drive (SSD) 2GB SATA III FLASH - NAND (SLC) mSATA 3.3V 制造商:apacer memory america 系列:mSATA H1 零件状态:有效 存储容量:2GB 存储器类型:FLASH - NAND(SLC) 外形尺寸:mSATA 速度 - 读取:65MB/s 速度 - 写入:40MB/s 电压 - 电源:3.3V 类型:SATA III 电流 - 最大值:205mA(标准) 工作温度:0°C ~ 70°C 重量:- 大小/尺寸:50.80mm x 29.85mm x 1.35mm 标准包装:1

APM002GM1AN-2TW

功能描述:Solid State Drive (SSD) 2GB SATA III FLASH - NAND (SLC) mSATA 3.3V 制造商:apacer memory america 系列:mSATA H1 零件状态:有效 存储容量:2GB 存储器类型:FLASH - NAND(SLC) 外形尺寸:mSATA 速度 - 读取:65MB/s 速度 - 写入:40MB/s 电压 - 电源:3.3V 类型:SATA III 电流 - 最大值:205mA(标准) 工作温度:-40°C ~ 85°C 重量:- 大小/尺寸:50.80mm x 29.85mm x 1.35mm 标准包装:1

APM004GM1AN-2T

功能描述:Solid State Drive (SSD) 4GB SATA III FLASH - NAND (SLC) mSATA 3.3V 制造商:apacer memory america 系列:mSATA H1 零件状态:有效 存储容量:4GB 存储器类型:FLASH - NAND(SLC) 外形尺寸:mSATA 速度 - 读取:130MB/s 速度 - 写入:75MB/s 电压 - 电源:3.3V 类型:SATA III 电流 - 最大值:250mA(标准) 工作温度:0°C ~ 70°C 重量:- 大小/尺寸:50.80mm x 29.85mm x 1.35mm 标准包装:1